THE ULTIMATE IN INTARSIA KNITTING TECHNOLOGY

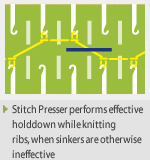

SHIMA SEIKI introduces a whole new benchmark in intarsia knit production with the MACH2SIR machine. As the name suggests, MACH2SIR offers unprecedented speed and efficiency. Maximum knitting speed is increased to 1.4 meters per second. The new R2CARRIAGE System achieves quicker carriage returns after each course. Intarsia knitting is dramatically improved through the use of up to 40 intarsia carriers. In addition, as part of the newest generation of SHIMA SEIKI knitting machines, MACH2SIR carries over all the technological achievements for which SHIMA SEIKI is made famous: DSCS Digital Stitch Control System; Full-Time Spring-Loaded Sinker System; Stitch Presser; Yarn Gripper and Cutter; Takedown System; and more. Finally, MACH2SIR offers a blend of Made-in-Japan quality and reliability, productivity, user-friendliness and cost-performance that fulfills the high expectations already held by the global fashion industry.